The Science of Smarter Cooling

Efficiency Retrofit for Walk-in Cold Storage

EnerG² retrofits to existing refrigeration thermostats to provide more accurate temperature control by simulating the temperature of food and beverages instead of ambient air. It utilizes a specialized gel compound with thermal properties like those of the products being refrigerated. It requires no maintenance and has a lifetime warranty.

Walk-in Coolers & Freezers + Other Cold Storage

15 - 25% Reduction in Energy

40 - 60% Reduction in Compressor Cycles

Increased Temperature Stability ~ Food Preservation

Lifetime Warranty

12-Month ROI

Tech IQ

EnerG² was the first technology Madison Energy designed and produced in 2010. It gained a great deal of attention for its simplicity, logical function, sleek design, and ease of installation. Historically, refrigeration has been controlled by air temperature. In a refrigerated space, the temperature of air, liquids, and solids can behave quite differently due to their unique properties.

Air temperature in a refrigerator can change relatively quickly, especially when the door is opened frequently. This is because air has a low specific heat capacity, meaning it doesn't require much energy to change its temperature. Additionally, the air temperature can fluctuate due to the cycling of the refrigeration system. When the compressor turns on, the temperature drops, and when it turns off, the temperature can rise slightly.

Liquids, on the other hand, have a higher specific heat capacity than air, meaning they require more energy to change temperature. As a result, liquid temperatures in a refrigerator are more stable and change more slowly than air temperatures. When the refrigerator door is opened, the liquid temperature will change more slowly compared to the air temperature, as it takes longer for the liquid to absorb or lose heat.

Solids have the highest specific heat capacity and thermal mass among the three, meaning they can absorb and store a significant amount of heat energy, leading to very stable temperatures. The temperature of solids in a refrigerator changes very slowly, and even when the door is opened, it takes a considerable amount of time for the solid temperature to be affected.

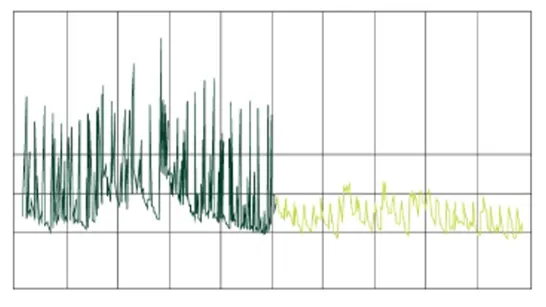

Temperature BEFORE and AFTER EnerG²

Comparison:

Air: Rapid and frequent temperature changes due to low specific heat capacity and frequent door openings.

Liquid: More stable temperature changes, slower than air but faster than solids.

Solid: Most stable and slowest temperature changes due to high specific heat capacity and thermal mass.

The Solution - EnerG²

The thermal properties of the gel contained within the EnerG² function as a blend of liquid and solid temperatures which fluctuate with more stability than air (gas). This creates a more stable temperature environment that requires less energy to maintain. With the EnerG² installed, compressor cycles have been documented to be reduced by 40-60%. This represents unnecessary runtime that has been eliminated, equating to significant energy and maintenance savings.

EnerG² Testing Partners

HQ

710 East Main St.

Lexington, KY 40502

877-247-3007

FOLLOW US

COMPANY

CUSTOMER CARE

LEGAL

Copyright 2026. Madison Energy. All Rights Reserved.