SUPERIOR PERFORMANCE; LASTING PROTECTION

Dual Synthetic Refrigerant Additive

SynCat360 is an innovative solution designed to improve the efficiency of refrigerant based systems. This includes both HVAC and refrigeration systems. It works by enhancing the heat transfer process within these systems, leading to reduced energy consumption and lower operational costs. SynCat360 achieves this by addressing the issue of oil fouling, which occurs when oil from the compressor coats the inner surfaces of heat exchangers, reducing their efficiency. By eliminating oil fouling, SynCat360 ensures that the heat exchangers operate at their optimal performance, resulting in significant energy savings and extended equipment lifespan. This technology is particularly beneficial for commercial and industrial applications, where energy efficiency and cost savings are critical.

HVAC and Refrigeration Applications

10 – 30% Energy Reduction

Eliminates Oil Fouling

Accelerates Charge of Refrigerant

Extends Equipment Life

Lifetime Warranty

18-Month ROI

Tech IQ

SynCat360 is an advanced synthetic catalyst that enhances HVAC compressor performance by breaking down oil particles and restoring viscosity. It features two catalysts: one removes oil fouling to keep heat exchange surfaces clean, and the other accelerates refrigerant heat absorption for faster setpoint achievement and energy savings. Additionally, nanoparticles fill cracks and bond to refrigerant lines and coils, extending equipment life by preventing leaks and degradation.

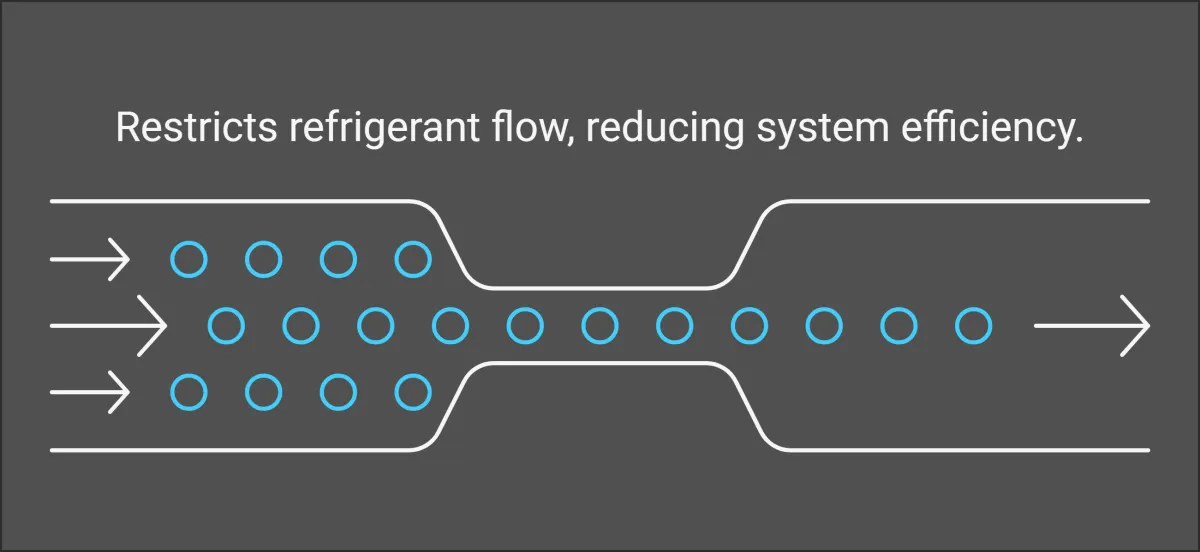

Oil fouling occurs when oil from the compressor in HVAC and refrigeration systems coat the inner surfaces of heat exchangers. This layer of oil acts as an insulating barrier, reducing the efficiency of heat transfer between the refrigerant and the air or water being cooled. The negative effects of oil fouling include increased energy consumption, as the system has to work harder to achieve the desired cooling effect. This leads to higher operational costs and can also shorten the lifespan of the equipment due to the added strain on the compressor and other components. Additionally, oil fouling can result in uneven cooling, which may affect the quality and safety of stored products in commercial and industrial applications. Regular maintenance and the use of technologies designed to mitigate oil fouling can help maintain optimal system performance and energy efficiency.

Example of Oil Fouling

SynCat360 Testing Partners

HQ

710 East Main St.

Lexington, KY 40502

877-247-3007

FOLLOW US

COMPANY

CUSTOMER CARE

LEGAL

Copyright 2026. Madison Energy. All Rights Reserved.